Submerged Arc Furnace (SAF)

The submerged arc furnace is an industrial electric furnace that consumes a lot of power.

It mainly consists of a furnace shell, fume hood, furnace lining, short net, water cooling system, smoke exhaust system, dust removal system, electrode shell, electrode pressing and lifting system, loading and unloading system, gripper, burner, hydraulic system, submerged arc furnace Transformers and various electrical equipment and other components.

Submerged arc furnace equipment is divided into three layers

The first layer is composed of the furnace body (including furnace bottom support, furnace shell, and furnace lining), tapping system (including ladle or pot and chartered car, etc.), burner, and other components.

Details Description

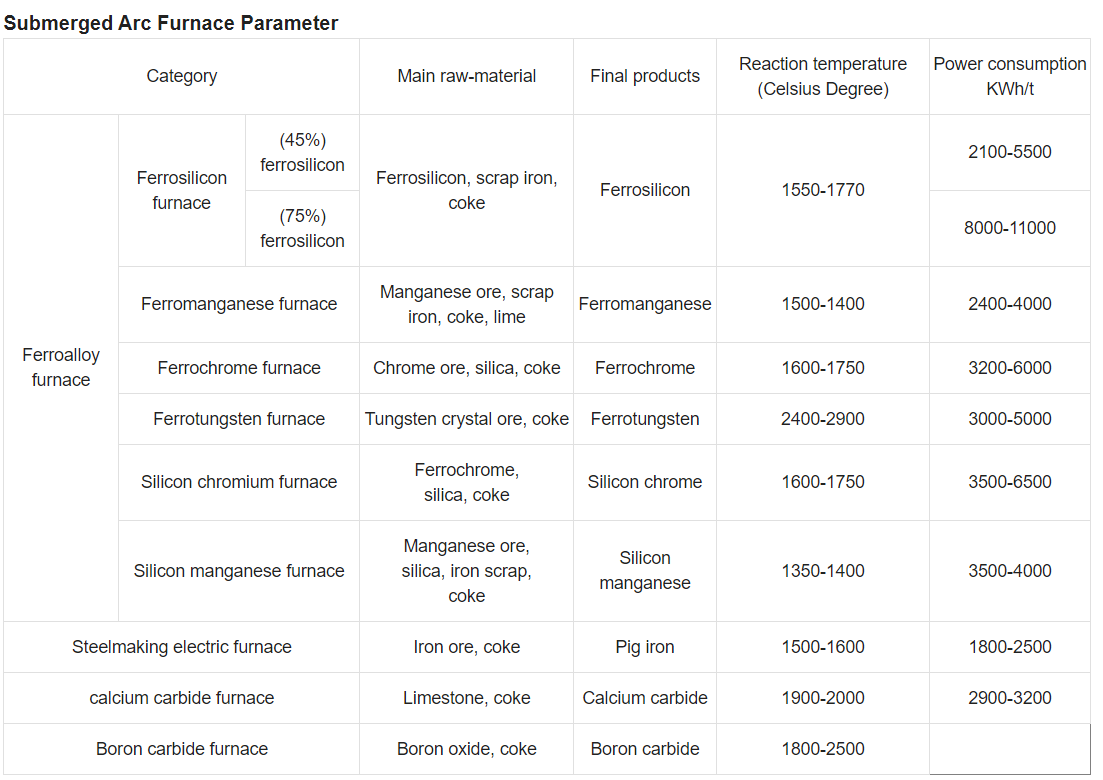

Submerged Arc Furnace is mainly used for reducing and smelting ore, carbonaceous reducing agents and solvents, and other raw materials. It mainly produces ferrosilicon, ferromanganese, ferrochromium, ferrotungsten, silicon-manganese alloy, and other ferroalloys, which are important industrial raw materials in the metallurgical industry and chemical raw materials such as calcium carbide.

Submerged arc furnace equipment is divided into three layers

The first layer is composed of the furnace body (including furnace bottom support, furnace shell, and furnace lining), tapping system (including ladle or pot and chartered car, etc.), burner, and other components.

The Second Floor

(1) Smoke hood.

(2) Electrode holder

(3) Short network

(4) copper tile

(5) Electrode shell

(6) Unloading system

(7) Inverter

(8) Smoke exhaust system

(9) Water cooling system

(10) Submerged arc furnace transformer

Operating System Layer 3

(1) Hydraulic system

(2) Electrode pressure release device

(3) Electrode lifting system

(4) Steel platform

(5) Hopper and circular distribution car Other accessories; Inclined bridge feeding system, electronic batching system

Parameters

Features

Submerged Arc Furnace's working feature is to uses carbon or magnesia refractory materials as the furnace lining and use self-cultivating electrodes. The electrode is inserted into the furnace material for submerged arc operation, using the energy and current of the arc to pass through the furnace material, and the energy generated by the resistance of the furnace material to smelt metal, feeding successively, intermittently tapping iron slag, an industrial electric furnace that operates continuously.