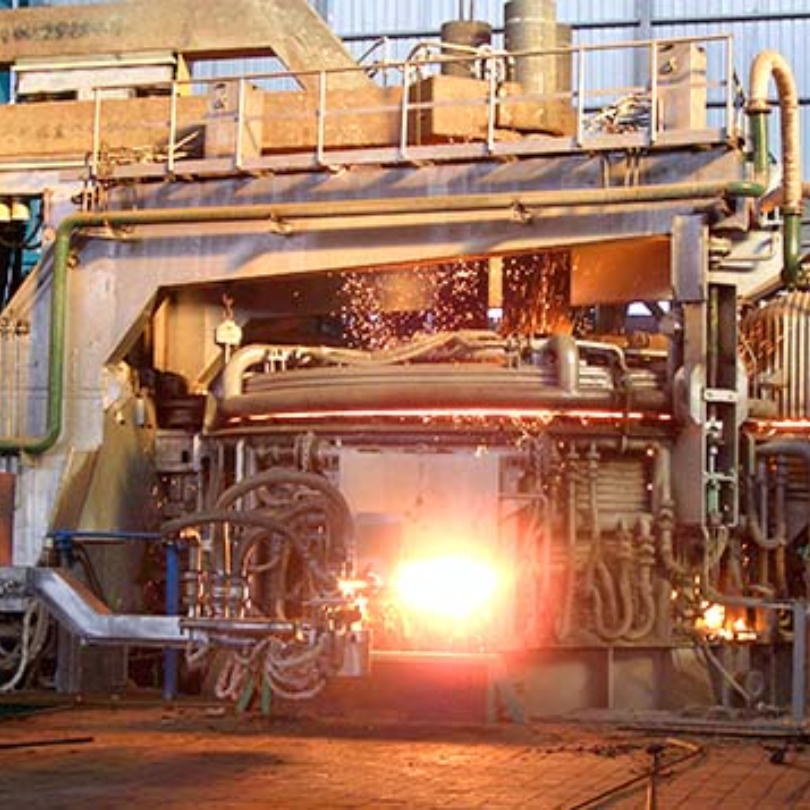

Industrial Furnace

Industrial furnace is thermal equipment for heating materials or workpieces by burning heat or electricity in industrial production.

Constituent part:

Industrial furnace masonry, industrial furnace exhaust system, industrial furnace preheater, industrial furnace drive and industrial furnace combustion devices.

Details Description

Industrial furnace is thermal equipment for heating materials or workpieces by burning heat or electricity in industrial production.

Industrial Furnace Constituent part:

- Industrial furnace masonry, furnace exhaust system, furnace preheater, furnace drive and furnace combustion devices.

- The structure of the general furnace is as follows: Furnace body, including frame supporting structure, furnace structure, material conveying system and so on.

- The heating system, including the equipment system which provides the heat source to the material in the furnace, such as the energy medium pipe and equipment system, the power transmission system pressure transformer and so on.

Smoke exhaust system, including flue, chimney, heat exchanger and smoke exhaust auxiliary equipment.

Other supporting equipment.

Parameters

Application classification

- In the foundry, there are cupola furnaces, induction furnaces, resistance furnaces, electric arc furnaces, vacuum furnaces, open hearth furnaces, crucible furnaces and the like; there are sand drying ovens of sand-type , iron alloy ovens and casting annealing furnaces;

- In the forging workshop, there are all kinds of heating furnaces for heating ingot or billet before forging, and heat treatment furnace to eliminate stress after forging.

- In the metal heat treatment workshop, there are various heat treatment furnaces for annealing, normalizing, quenching and tempering to improve the mechanical properties of the workpiece.

- In welding workshop, there are pre welding preheating furnace and welding tempering furnace for welding parts.

- In the powder metallurgy workshop there are furnaces for sintering metal, etc.

Features

Equipment classification:

- Industrial furnaces are divided into two types according to the heating mode: one is a flame furnace (or fuel furnace), and the workpiece is heated by the combustion heat of a solid, liquid, or gaseous fuel in the furnace; the second type is an electric furnace in which the electrical energy is converted into heat for heating.

- Industrial furnaces are divided into two categories according to the thermal system: The one is intermittent furnaces, also known as cycle furnaces, which are characterized by the fact that the furnace chamber is not divided into temperature sections and the production is conducted on one or two shifts, and the furnace temperature varies in every heating period, such as various chamber furnaces, trolley furnaces, pit furnaces, bell furnaces, etc.

- The other is the continuous furnace, which is characterized by the division of temperature within the furnace, generally consists of three sections: preheating, heating (high temperature ), soaking (insulation). The production is continuous for three shifts. In the heating process of industrial furnace, the temperature in each section is not changed, such as two or three continuous heating furnace, push rod type heating furnace, heat treatment furnace, ring furnace and step. Furnace, shaker hearth furnace, cupola and lime kiln etc.