Introduction

Welcome to the ultimate rolling mills guide! In this comprehensive article, we will explore everything you need to know about rolling mills and their importance in various industries. From their history and types to the working principle and maintenance, we've got you covered. So, let's dive into the fascinating world of rolling mills.

A Brief History of Rolling Mills

The concept of rolling mills dates back to ancient times when the first metalworking machinery was developed. Early civilizations used simple tools to shape metals, but it wasn't until the 17th century that the first rolling mills were invented. Since then, these mills have undergone significant advancements and have become indispensable in various industries.

The Different Types of Rolling Mills

Rolling mills come in different types, each designed for specific purposes. Some common types include:

- Two-High Rolling Mills

- Three-High Rolling Mills

- Four-High Rolling Mills

- Cluster Rolling Mills

- Tandem Rolling Mills

Each type has its unique features and applications, ensuring efficient and precise metal shaping and processing.

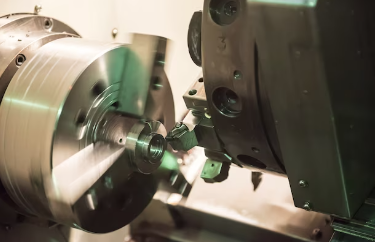

The Working Principle of Rolling Mills

Rolling mills operate on a simple yet ingenious principle. A metal billet or ingot is passed between two rotating rolls, which exert pressure and compress the material. This continuous process reduces the thickness and shapes the metal into the desired form. The rolls can be smooth or grooved, depending on the desired finish and product requirements.

The Applications of Rolling Mills

Rolling mills find extensive use in various industries, including:

- Steel Manufacturing

- Aluminum Production

- Automotive Industry

- Jewelry Making

- Construction

From producing steel sheets and bars to shaping aluminum components and creating intricate jewelry designs, rolling mills play a crucial role in modern manufacturing processes.

The Importance of Maintenance for Rolling Mills

Maintaining rolling mills is essential for their optimal performance and longevity. Regular inspections, lubrication, and cleaning are necessary to prevent wear and tear, minimize downtime, and ensure consistent product quality. Proper maintenance also helps identify and address any potential issues before they escalate, saving both time and money in the long run.

Choosing the Right Rolling Mill for Your Needs

Choosing the right rolling mill depends on various factors, including:

- Material Type and Thickness

- Production Volume

- Desired Finish and Precision

- Available Space

Considering these factors will help you select a rolling mill that perfectly suits your specific requirements, maximizing productivity and efficiency.

Safety Precautions When Operating Rolling Mills

Working with rolling mills involves potential hazards, and it is crucial to prioritize safety. Some essential safety precautions include:

- Wearing Personal Protective Equipment (PPE)

- Proper Training and Familiarity with the Equipment

- Using Guards and Safety Devices

- Maintaining a Clean and Organized Workspace

By following these precautions, accidents and injuries can be minimized, ensuring a safe working environment.

Trends and Innovations in Rolling Mills

The field of rolling mills is continuously evolving with advancements in technology and new innovations. Some recent trends include:

- Automation and Robotics

- Advanced Control Systems

- Enhanced Material Handling

- Energy Efficiency

These advancements improve productivity, precision, and sustainability in rolling mill operations, making them more efficient and environmentally friendly.

The Future of Rolling Mills

As industries continue to evolve and demand higher quality products, the future of rolling mills looks promising. With ongoing research and development, we can expect further improvements in efficiency, precision, and automation. Rolling mills will continue to play a vital role in shaping the metals that drive our modern world.