High carbon steel cold rolled products are a key component in various industries due to their exceptional properties and versatility. This type of steel is widely used across different sectors, including automotive, construction, and manufacturing. In this article, we will explore the characteristics, applications, and benefits of high carbon steel cold rolled products.

High carbon steel is defined as steel with a carbon content exceeding 0.30%. This higher carbon content provides the steel with increased strength and hardness, making it suitable for applications that require resistance to wear, abrasion, and impact. Cold rolling is a process that further enhances the properties of high carbon steel by subjecting it to compression and cooling at room temperature, resulting in a smoother surface finish and improved dimensional accuracy.

One of the primary applications of high carbon steel cold rolled products is in the automotive industry. These products are commonly used in the manufacturing of automobile parts that require high strength and durability, such as crankshafts, gears, and springs. The excellent wear resistance of high carbon steel ensures that these components can withstand the demanding conditions of the automotive environment, contributing to the overall performance and longevity of vehicles.

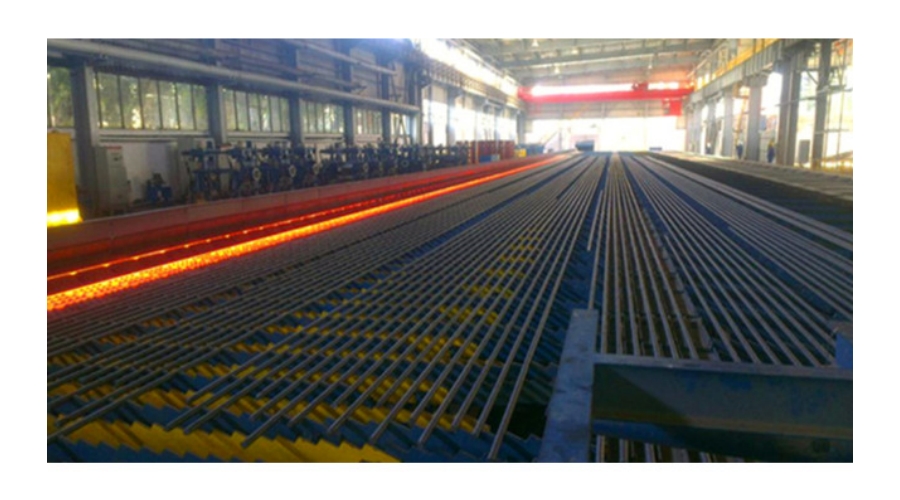

In the construction industry, high carbon steel cold rolled products find application in various structural components. For example, they are used in the production of reinforcing bars (rebars) that are essential for reinforcing concrete structures like bridges, buildings, and highways. The strength and toughness of high carbon steel ensure that these structures can withstand heavy loads and provide long-lasting support.

Another significant application of high carbon steel cold rolled products is in the manufacturing sector. These products are used to produce a wide range of tools and equipment, including cutting tools, drill bits, saw blades, and springs. The hardness and wear resistance of high carbon steel make it an ideal choice for these applications, as it allows the tools to maintain their sharpness and performance even under high-stress conditions.

The benefits of using high carbon steel cold rolled products extend beyond their mechanical properties. Cold rolling enhances the surface finish of the steel, resulting in a smoother and more aesthetically appealing product. This makes high carbon steel cold rolled products suitable for applications that require a high level of precision and a polished appearance.

Furthermore, the cold rolling process also improves the dimensional accuracy of high carbon steel, allowing manufacturers to achieve tight tolerances and consistent product quality. This is crucial for industries where precise measurements are essential, such as aerospace and electronics manufacturing.

High carbon steel cold rolled products also offer excellent machinability, allowing for ease of processing and fabrication. This makes it easier for manufacturers to shape the steel into desired forms and sizes, reducing production time and costs.

In conclusion, high carbon steel cold rolled products are highly valued in various industries due to their exceptional properties and versatility. The combination of high strength, hardness, wear resistance, and improved surface finish makes them ideal for automotive, construction, and manufacturing applications. Furthermore, the benefits of cold rolling, including enhanced dimensional accuracy and machinability, further contribute to the appeal of high carbon steel cold rolled products. As industries continue to demand materials that can withstand extreme conditions and provide superior performance, high carbon steel cold rolled products will undoubtedly remain a cornerstone in the production of high-quality and durable goods.